Applications and technologies

High quality, high performance metal powders for your manufacturing needs

We have experts dedicated to developing metal powders for a variety of applications and technologies. And, we are continually upgrading and fine-tuning processes and products currently on the market.

Press and sintered parts

Rio Tinto Metal Powders has a number of press-ready powder mixes, including our Synergy® Series. Compared to conventional metal powder lubricants, Synergy® Series mixes have improved apparent density and more stable flow properties.

Additive manufacturing

Metal additive manufacturing is growing significantly in industrial markets. Our mission is to help industries adopt this technology, even where cost is a key driver. Rio Tinto Metal Powder’s low-cost ferrous water atomized powders are the real solution for industrial adoption of additive manufacturing.

Soft magnetic composites

Soft magnetic composites (SMCs) are manufactured by pressing electrically-insulated iron-based metal powders into parts. You can find our metal powders in electric motors and other products where you need small parts with highly accurate composition.

Welding, alloying, recovery, and flame cutting

Our high purity iron powders improve weld metal in coated welding electrodes, flux cored and metal cored wires, and filler metals. This addition will result in a more stable arc with lower spatter. Iron powder can also contribute to mechanical properties of the weld. Our powders can be used in welding process wires including SMAW, FCAW, MCAW.

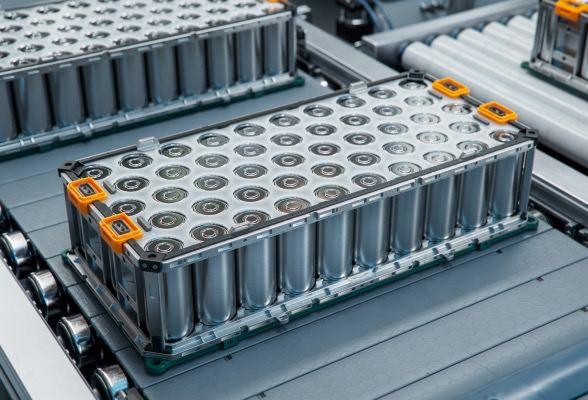

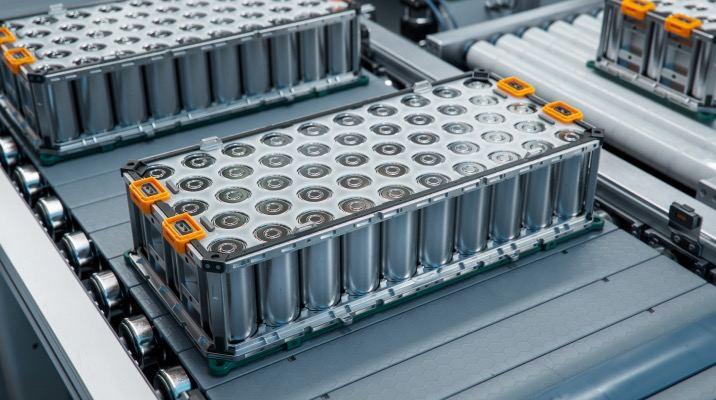

Lithium iron phosphate batteries

Iron powders play a crucial role in the production and performance of lithium iron phosphate (LFP) batteries. Using iron powder in cathode material contributes to electrode density and conductivity. Iron-based materials in LFP batteries are considered more environmentally friendly compared to other materials used in batteries, as iron is abundant and less toxic. They help in creating a stable, efficient, and environmentally friendly energy storage solution.

Stationary energy storage

Iron-air batteries are a type of stationary energy storage technology that uses iron powder as a key component. Iron-air batteries can offer high energy density, making them suitable for large-scale energy storage applications, such as renewable energy systems and grid stabilization.

Iron as fuel

As a potential alternative to carbon fuels, iron powders could be used to produce clean energy. Iron can be burned at high temperatures so it can directly replace coal in coal-fired boilers. Yet, iron emits no toxic chemicals. Easy to store and transport, Rio Tinto Metal Powders have a high energy density, and can be burned almost indefinitely depending on the application.

Oxygen absorbers

Added to air-tight packaging, oxygen absorbers help maintain product stability. As the primary component, iron powder reacts with sodium and turns to rust. This process reduces the available oxygen level in the package.

Customized product development

At Rio Tinto, our technical and scientific experts are dedicated to continuous research and product improvement to meet our customers’ exacting specifications. In collaboration with industry leaders, we constantly explore new ways to optimize our metal powders in your existing applications—and your future innovations.